Bottling lines

Fill out the form to download the information pack on ACMI SpA

Thank you for filling in the form

Click here to download the fileBottling lines

Phases of the Bottling

Process thanks to our bottling line equipment:- Container Preparation

Cleaning and Sanitisation: Prior to bottling, containers are thoroughly cleaned and sanitised to remove impurities and contaminants. Inspect containers to identify any defects or damage. - Filling

Product Dosing: Product is accurately dosed to ensure uniform filling of each container. Beverage producers use isobaric filling for carbonated drinks and gravity filling for non-carbonated drinks. - Closure

Caps close containers, such as screw caps, crown caps, or other types of closures, based on the product requirements.

Tightness Check: The tightness is checked to ensure that there are no leaks. - Labelling and Marking

Label Application: Labels are applied automatically, ensuring precise and uniform positioning.

Date Marking: The production and/or expiry date is imprinted to ensure product traceability. - Packaging

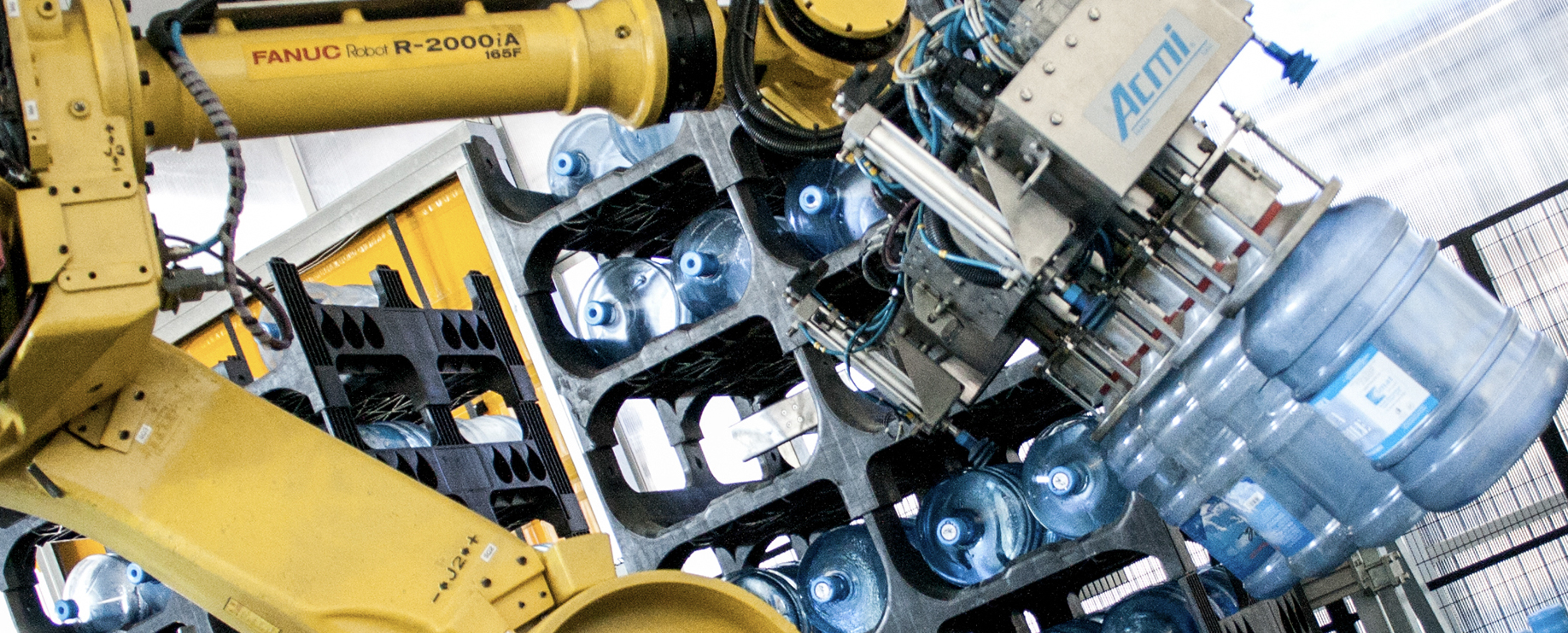

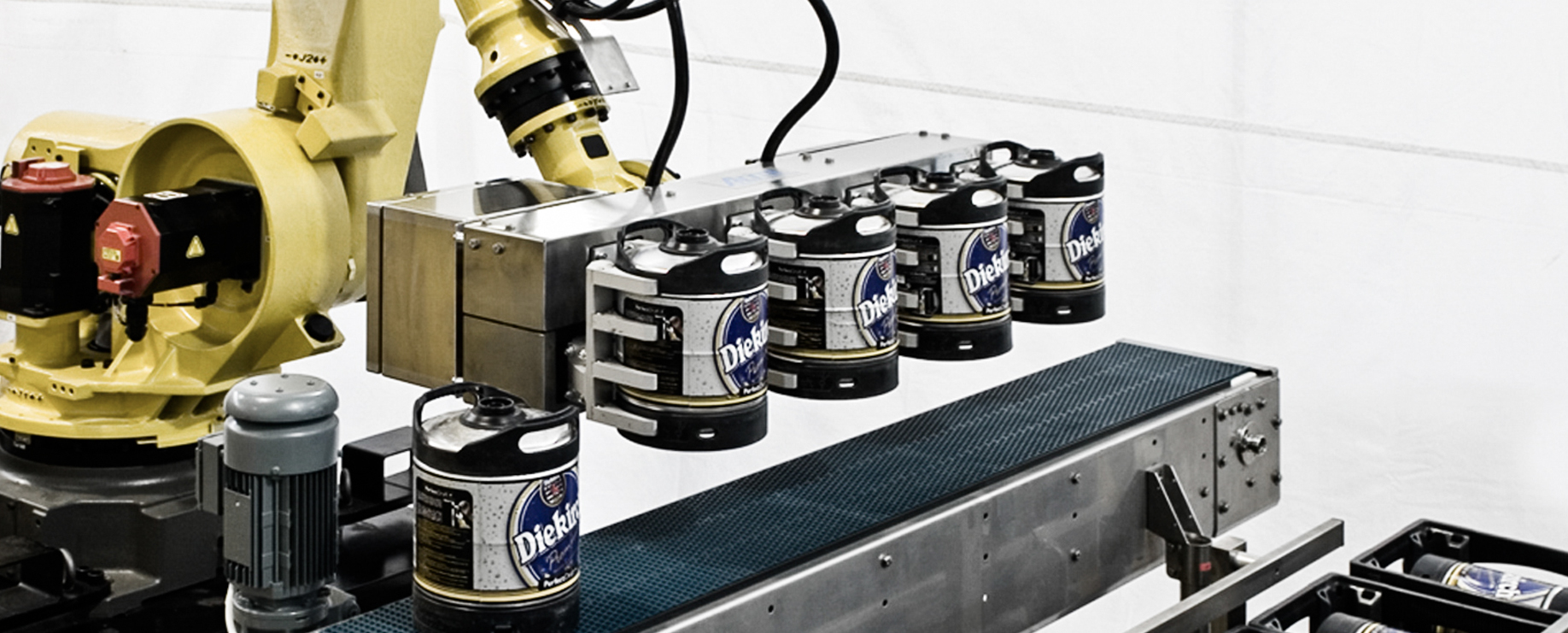

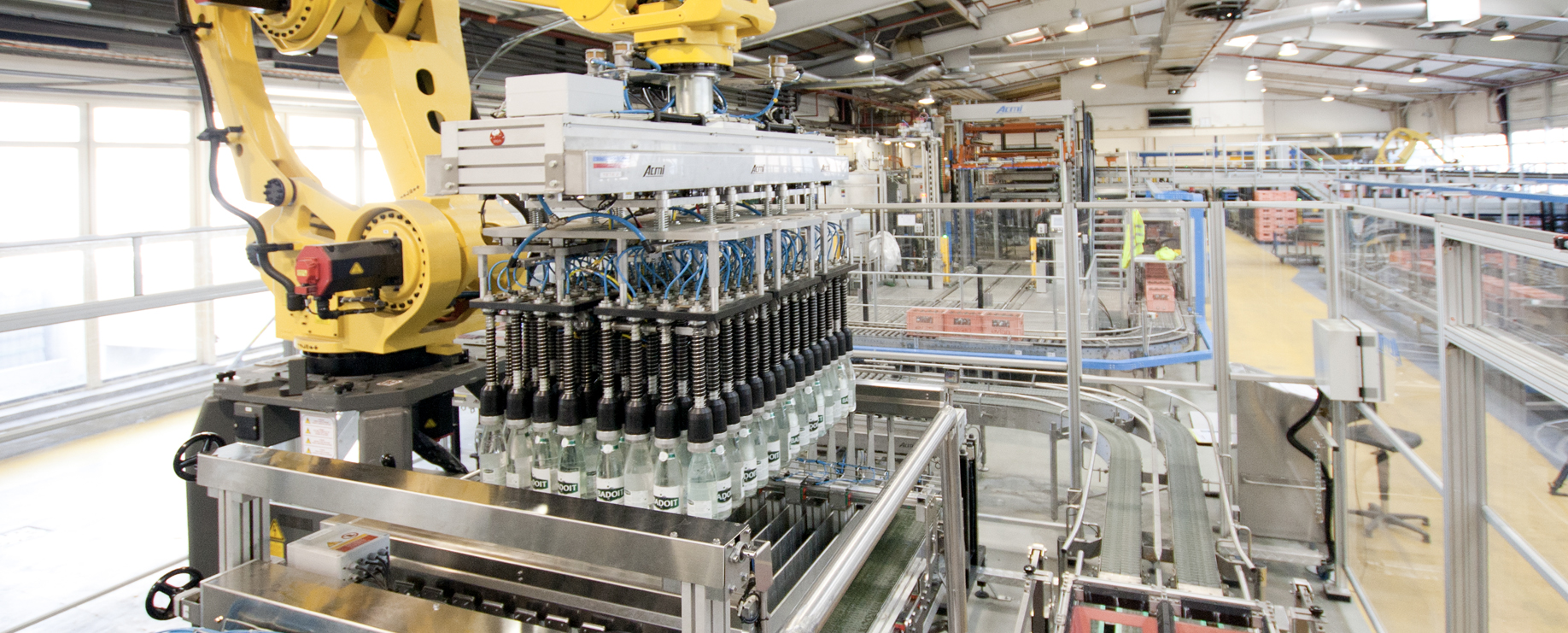

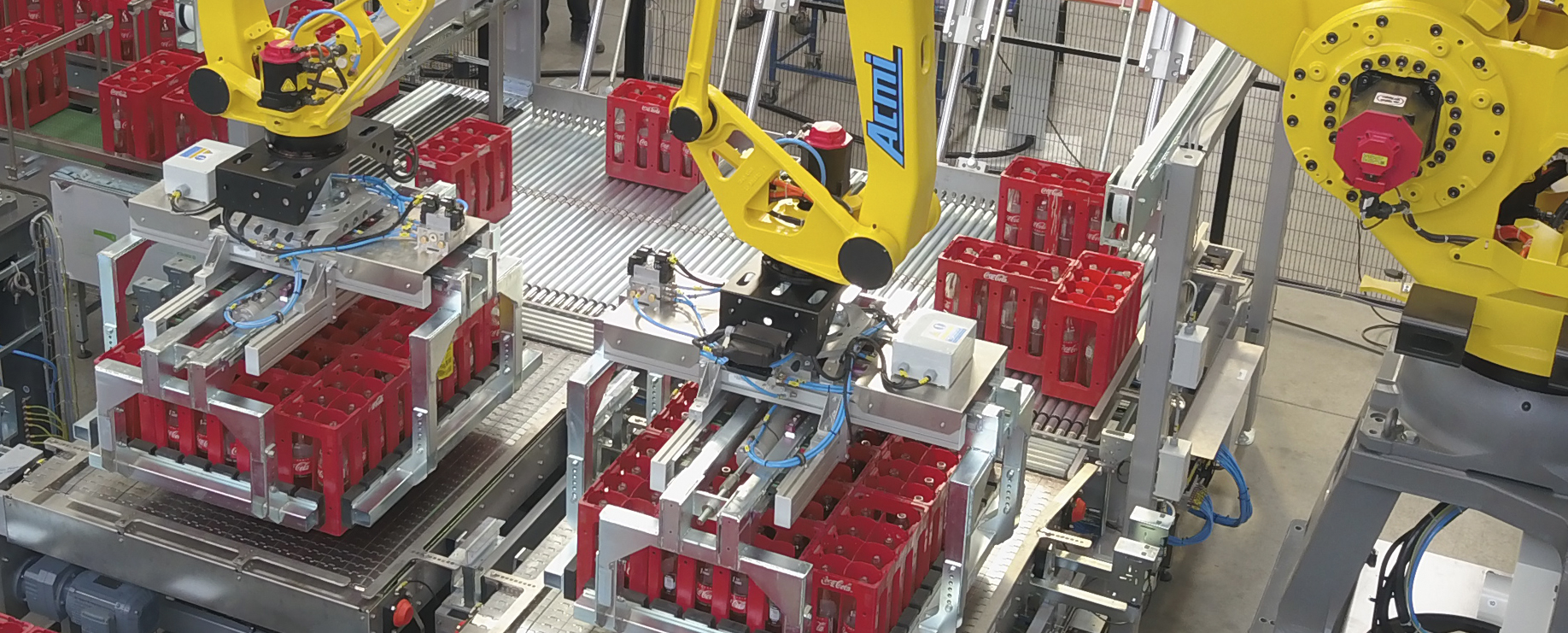

Packaging in Cartons or Crates: Bottled containers are organised in cartons or crates for easy transport.

Palletising and Twisterbox: The cartons or crates are arranged on pallets for efficient logistics management.

Technology and Innovations

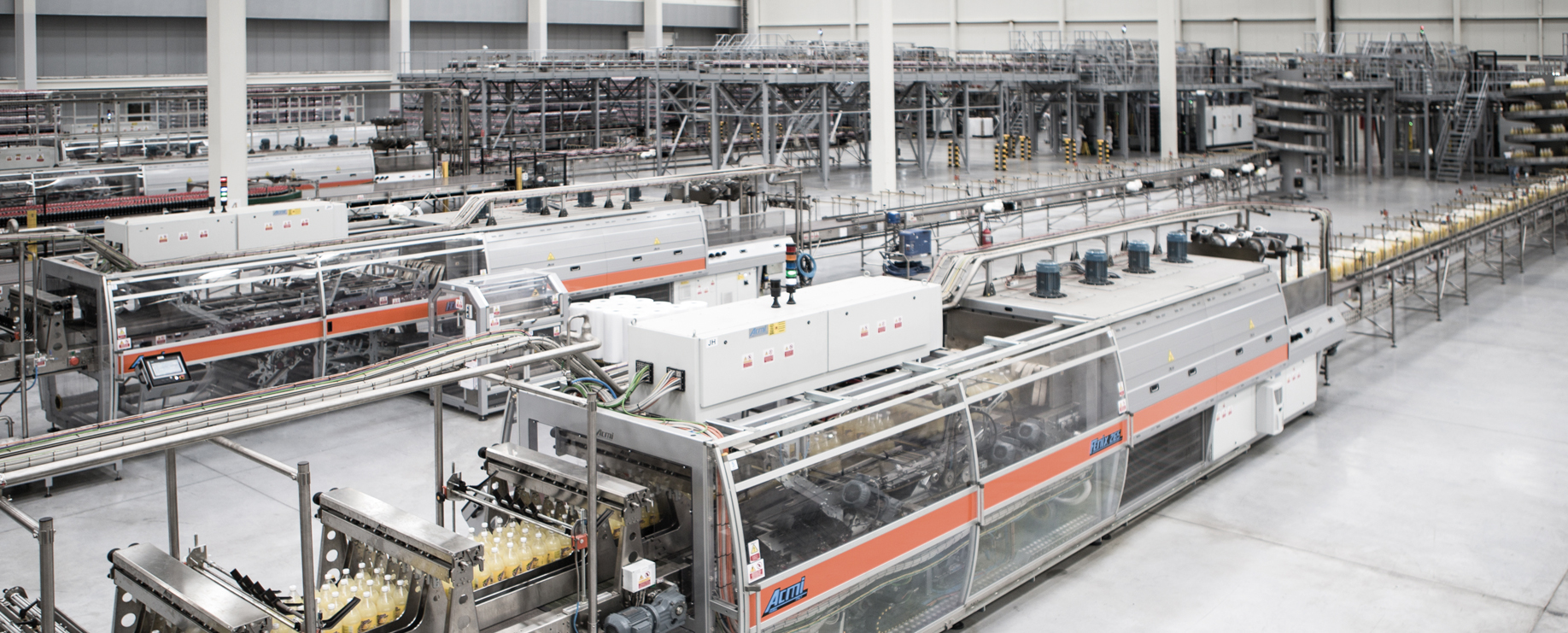

Modern bottling lines integrate advanced technologies to optimise the process and improve the quality of the end product:- Automated Control Systems: They monitor and regulate every step of the process, reducing human error and increasing productivity.

- Sensors and Detectors: Used for quality control, detecting impurities, defects in containers and other anomalies.

- Traceability Systems: Allow each production batch to be tracked, improving stock management and facilitating product recalls.

Advantages of our Modern Bottling Lines machinery

- Operational Efficiency: Reduced downtime and increased bottling speed.

- Constant Quality: Ensures uniformity in filling and closing containers.

- Food Safety: Minimises the risk of contamination while complying with regulations.

- Flexibility: Adaptable to different product types and container sizes.

In short, bottling lines are crucial for the beverage and liquid food industry. They use advanced technology from Italy and strict quality control to meet consumer demands and industry rules.

Click here to download the information pack on ACMI SpA

DOWNLOADFill out the form to download the information pack on ACMI SpA

Thank you for filling in the form

Click here to download the fileRequest more information on end-of-line solutions, complete lines and single machines

CONTACT USContact us to ask for more information

Grazie per averci contattato

I would like to be contacted by one of ACMI’s sales representatives

SENDFill out the form below to be contacted by an ACMI sales representative

Grazie per averci contattato