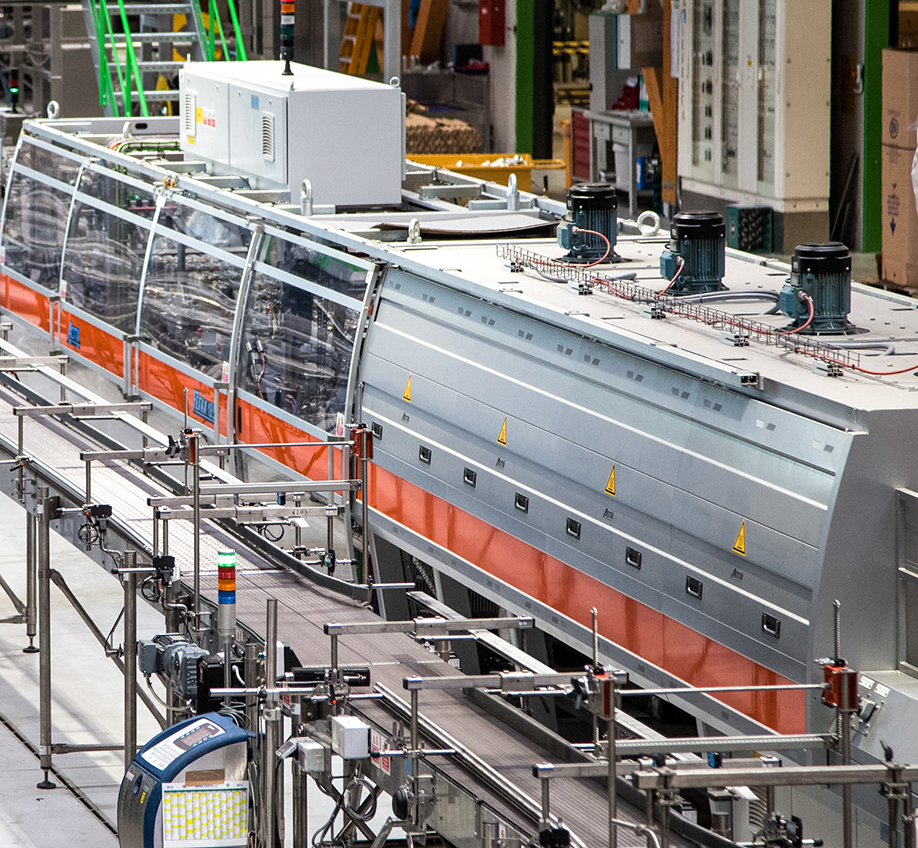

Can lines

Our can lines are tested to support nominal filling speeds of up to 120,000 pieces per hour, they are suitable for all sectors and have a very low TCO (Total Cost of Ownership). We integrate the “dry” part of the line, but we can also manage the installation of the entire system as project manager. Our innovative solutions make it possible to handle cans with any type of packaging, even without film, with considerable savings on secondary packaging and a significant reduction in environmental impact.