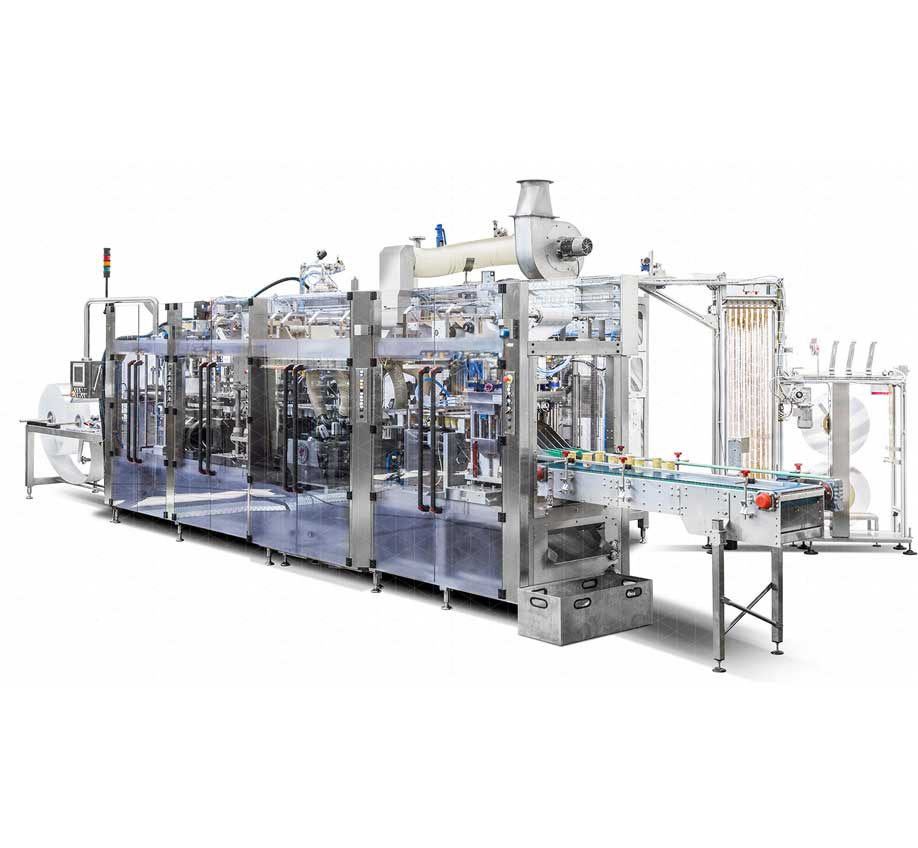

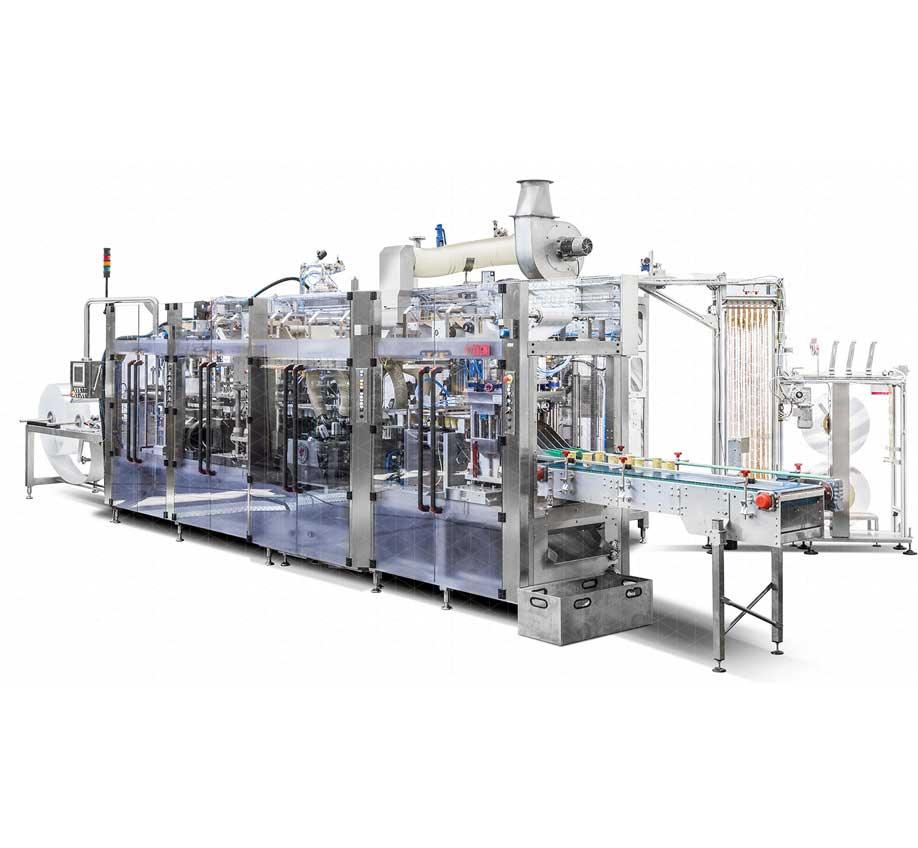

FORM-FILL-SEAL

The Form Fill & Seal machine combines thermoforming, filling, sealing and labelling operations in a single platform, offering a safe, high-performance solution for beverage, food and dairy products. It is compatible with a wide range of resins such as PS, PP and PET, and guarantees a high level of flexibility and adaptability. In terms of hygiene safety, several configurations are available: the ultra-filtered air configuration and the Extended Shelf Life (ESL) configuration with sterile pressurised air ensure maximum product durability and quality, while the fully aseptic configuration eliminates the risk of contamination by external agents. In addition, the ISA device is able to apply shrink sleeve labels to packages and perform multi-pack decoration thanks to a special optical recognition system.

Detail

ACMI Form Fill Seal Technology – FFS Machine

ACMI’s Form Fill Seal (FFS) machine is a complete packaging solution that combines thermoforming, filling, sealing and decorating in a single compact unit. Designed for the food, beverage and dairy industries, this advanced system ensures maximum productivity — from 6,000 to 100,000 containers per hour — while reducing film and plastic use through the innovative Clamp & Pull system. Highly flexible, the ACMI FFS works with all major plastic resins (PS, PP, PET) and is available in standard, hygienic, ESL and fully aseptic configurations. Its modular design allows fast changeovers, easy maintenance and a high level of hygiene with CIP and sterilisation options. Compatible with a wide variety of products, from yogurt and pudding to sauces and juice, ACMI’s Form Fill Seal machine delivers exceptional reliability, sustainability and efficiency across all production sectors.Speed of up to 100,000 bph. For beverage, dairy and food products.